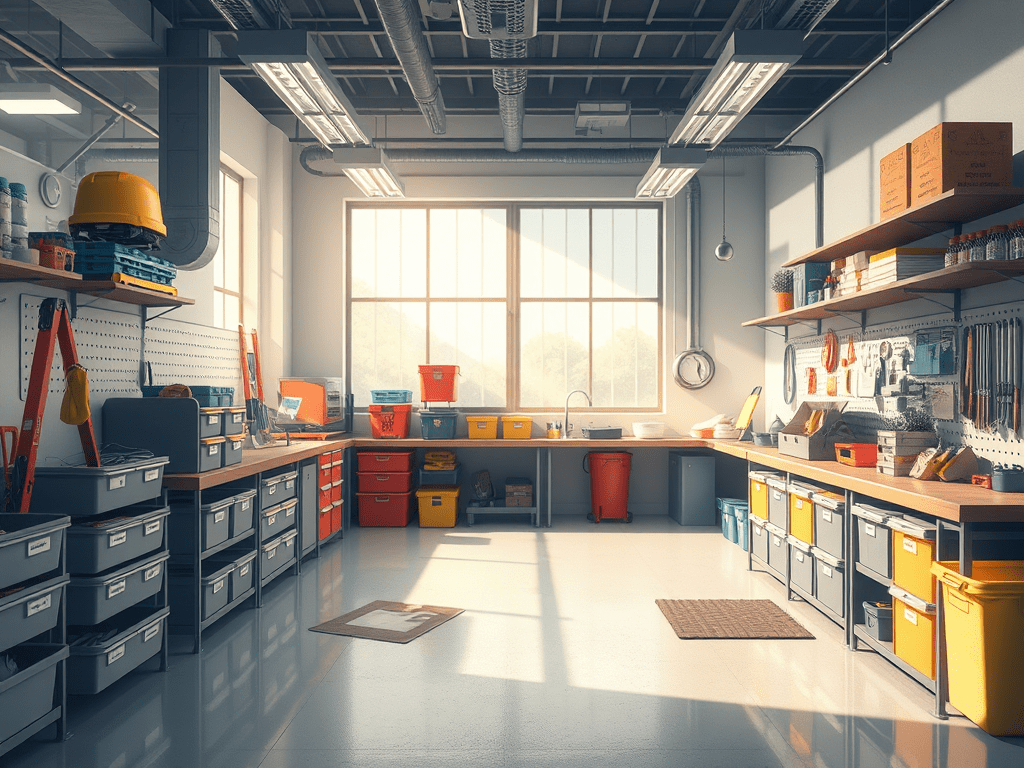

An efficient, safe and well-organized workplace is the key to success in today’s fast-paced world. This is exactly where the 6S method comes in. It is a proven system inspired by the Japanese concept of Kaizen. This method focuses on continuous improvement and eliminating waste. Whether factory, office or workshop – the 6S method transforms every workplace into a productive, well-oiled machine.

Find out how the six steps of the method can sustainably improve your working environment and leave a lasting impression.

1. Sort: Eliminate the unnecessary, create clarity

The basis for an optimized workplace is order. Start by sorting: Separate the important from the unimportant.

- Why?: Clutter is distracting and time-consuming. With a tidy workplace, you and your employees can concentrate on the essential tasks.

- How can you do this?

- Divide items into categories such as necessary, superfluous and reusable

- Remove anything that does not contribute to daily ope

rations

- Pro tip: Use colored markers or labels to make the process clearer.

2. Create order: Everything has its place

Sorting is followed by organizing: Give each item a fixed place.

- Why?: A clearly structured workplace increases efficiency and reduces search times and unnecessary movements.

- How?

- Organize frequently used utensils within easy reach and less used items in the background

- Support the organization with tool walls, labels or floor markings.

- Practical example: kitchen professionals place knives, spices and pans within easy reach – no unnecessary running around, just precise work.

3. Shine: cleanliness as the basis for quality

A clean workplace is a productive workplace. Shine by cleaning and maintaining it regularly.

- Why?: Cleanliness not only enhances aesthetics, but also extends the service life of your work equipment and ensures a pleasant working environment.

- How?

- Establish a daily cleaning routine for work surfaces, machines and tools.

- Carry out regular maintenance to identify problems at an early stage.

- Additional benefit: A clean environment reduces the risk of accidents and illness – a benefit for health and morale.

4. Standardize: Uniformity is key

To ensure that tidiness and cleanliness do not remain one-off actions, standardization ensures long-term results.

- Why: Standardized processes lead to consistent quality and avoid errors.

- How?

- Develop clear rules and checklists for the individual steps.

- Use visual aids such as posters or reminders to keep standards present.

- Pro tip: Involve your employees to create practicable and accepted standards.

5. Persevere: Live sustainable improvement

The best systems are useless if they are not practiced. The secret of success lies in perseverance.

- Why: Without sustainable measures, a workplace quickly falls back into old patterns.

- How?

- Train your employees regularly and remind them of the benefits of the 6S methodology.Reward teams that adhere to standards in an exemplary manner and celebrate successes.

- Conduct regular audits and progress reviews.

- Motivational idea: Don’t think of 6S as a destination, but as a journey – every step takes you further.

6. Safety: protecting your employees and resources

Safety is the most important component of the 6S method and permeates every step.

- Why: Accidents at work not only cost money, but also trust and well-being.

- How?

- Conduct regular safety audits to identify and eliminate hazards.Ensure protective clothing and safety equipment is always to hand.

- Promote a safety culture where everyone takes responsibility.

- – Tip: Use visual warnings and emergency plans to keep safety precautions present.

The advantages of the 6S method

The 6S method is more than a tool – it’s a mindset that will revolutionize your workplace. With 6S you can:

- Minimize waste and maximize efficiency.

- Increase safety, quality and satisfaction.

- Create a culture of continuous improvement.

Get started today: Choose an area where you want to implement the 6S method. With each improvement, you will notice how the way you work changes – more efficiently, more safely and more sustainably.

Leave a comment